ISO-22476-1:2022 Geotechnical investigation and testing – Field testing: Part 1 Electrical cone and piezocone penetration test

We are pleased to announce that ConeTec can now perform cone penetrometer calibrations and fieldwork according to the new ISO-22476-1:2022 standard, titled “Electrical cone and piezocone penetration test.”

This technical blog outlines recent updates to the Cone Penetration Testing (CPT) standard, ISO 22476-1:2022. We will discuss its key elements, benefits, and ConeTec's approach to integrating this new standard into our CPT operations.

1.0 Introduction to the New ISO

The 2022 version of ISO 22476-1 introduces several key updates to refine and enhance CPT practices. These updates aim to increase the accuracy, reliability, and applicability of the CPT, supporting practitioners in assessing soil properties with a known level of uncertainty. This makes ISO 22476-1:2022 an excellent choice for high-risk, large-scale, or critical design projects.

2.0 Understanding 'Classes' of Cone Penetrometers

A significant change is the redefinition of the cone penetrometer classes and calibration requirements. Calibrations now integrate uncertainty measurements at each load step, effects of temperature, and corrections for bending. This offers several advantages in cone selection, penetrometer calibration and overall application, including:

- Standardization of Equipment Performance: Ensures consistency in equipment performance across various projects;

- Enhanced Comparability of Data: Facilitates direct comparison of data from similar class penetrometers, crucial for large-scale or longitudinal studies;

- Flexibility in Equipment Selection: Allows engineers to select appropriate equipment based on project requirements;

- Improved Risk Management: Reduces data error risks, enhancing safety, reliability, and efficiency in engineering decisions.

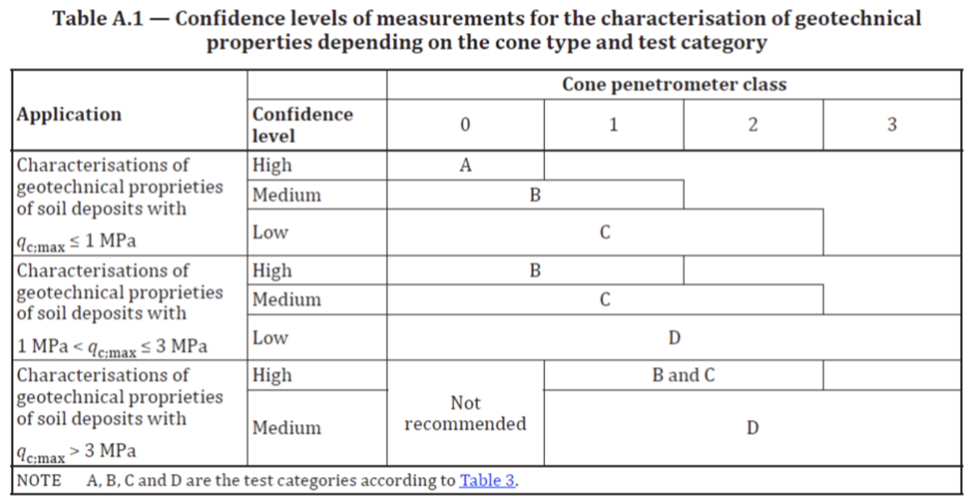

Table A.1 presents the expected confidence levels for soil characterisation, which can be used to guide the selection of the cone penetrometer class and test category.

Table A.1. Source: https://www.iso.org/obp/ui/#iso:std:iso:22476:-1:ed-2:v1:en

3.0 Understanding ‘Test Categories’ of the Cone Penetration Test

While a system for categorizing cone penetrometers into application classes existed previously, a new and critical feature to the 2022 standard is the introduction of a “test category” (A, B, C or D). The test category is targeted based on project requirements, which determines the class of cone penetrometer selected in combination with the required field procedures. Pre- and post-test zero load readings (deltas and stability), depth uncertainties and executed field QAQC measures are assessed to determine the test category achieved.

4.0 Thermal Stability and Transience

Thermal stability and thermal transience are also new additions to the standard. The 2022 revision introduces a greater focus on managing temperature effects, specifically addressing how temperature changes can affect CPT measurements. The standard includes guidelines on:

- Thermal stability: providing detailed procedures for assessing how temperature variations affect the performance and accuracy of cone penetrometers. This ensures that testing results remain reliable, even when there are changes in ambient or subsurface temperatures.

- Thermal transience: introducing considerations for temperature changes caused by frictional heating during penetration, which can lead to measurement errors. These transient effects are now accounted for, providing a framework for correcting or compensating for temperature-induced measurement drift.

This focus on temperature-related issues reflects the 2022 standard's efforts to enhance the accuracy of CPT measurements, particularly in challenging environments where temperature fluctuations can significantly impact data accuracy. This aspect was not explicitly covered in the ISO’s 2012 version.

5.0 Addressing a Gap in the Standard

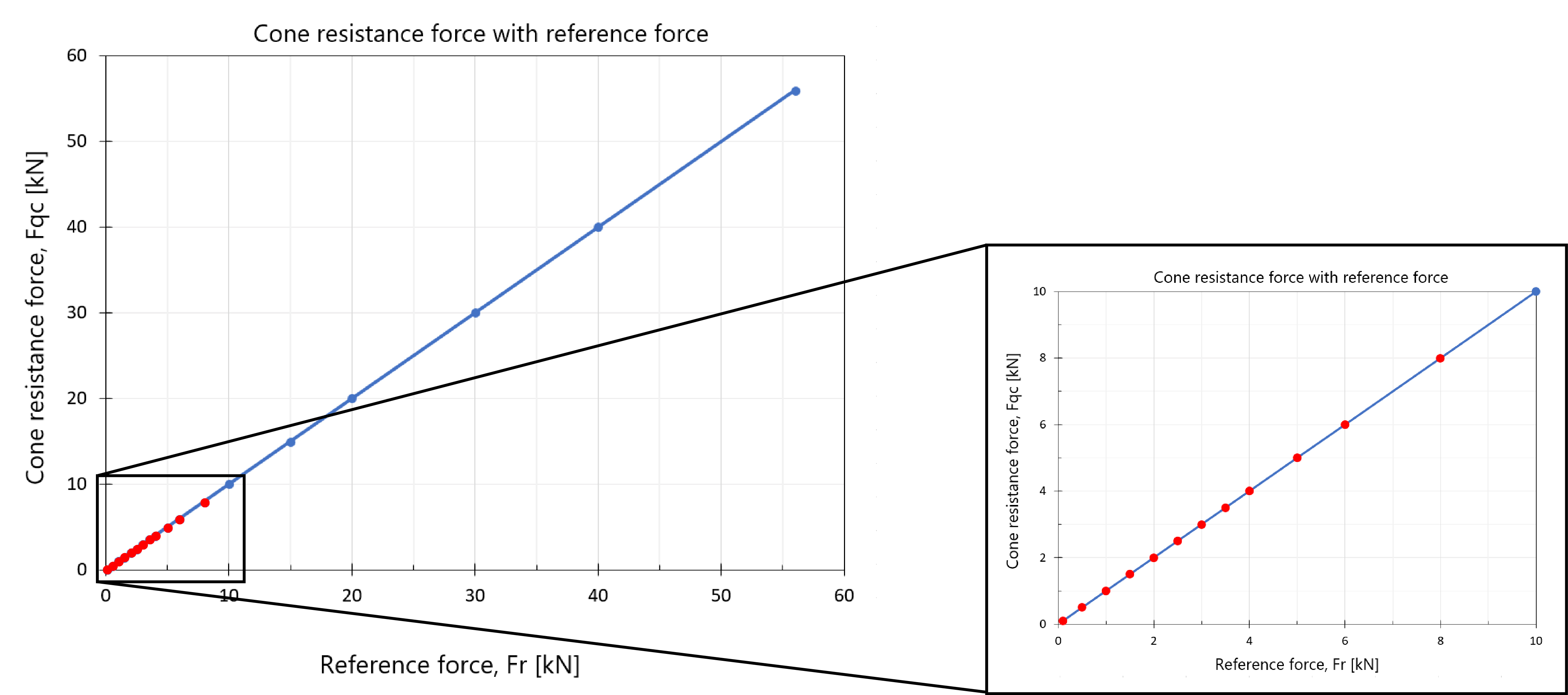

It is crucial to address the 2022 standard’s gap in assessing penetrometer performance at the low end. The standard asks for 100 evenly spaced calibration points. This may result in the first data point plotting above the stress range for soft soils. To address this, ConeTec exceeds the standard’s requirements and collects extra calibration points within the low-end range below the minimum specified point in the standard.

Plot 1: Example calibration results from the tip load cell showing additional points within the low end.

6.0 Key Points of ISO 22476-1:2022

The following is a summary of new key points to the 2022 ISO standard:

- Classifications for Penetrometers: Enhanced consistency and reliability across diverse projects;

- Sensor Performance: Offers more transparency in measuring capabilities, even for high-capacity instrument;

- Test Categories: Specifies new test categories for the CPTu

- Recommendations: Complements the mandatory requirements, offering users extended guidance.

The 2022 ISO standard also mandates three key field procedures:

- Stabilized Zero Values: Recording zero load values for 60 seconds at the start and end of each test to verify sensor stability;

- Updated Cone Dimensional Measurements: While the 2012 standard included guidance on cone dimension measurements for a prior definition of Application Class 1, the 2022 standard outlines new measurement criteria for surface area calculations and tolerance conformance; with actual penetrometer dimensions used for stress calculations.

- Depth Verification / Comprehensive Measurement Procedures: Assessment of actual penetration depth by monitoring the CPT probe's verticality, improving soil profiling accuracy. Previous guidance of depth verification was also presented in the 2012 ISO as a requirement of Application Class 1.

7.0 ConeTec’s Integration of ISO 22476-1:2022

ConeTec has integrated the new ISO standard into our procedures and QAQC protocols, enhancing our calibration capabilities and field operations. Our Quality Control and Quality Assurance program includes:

- Meeting or exceeding calibration standards, especially within the low-end range;

- Measuring temperature throughout the test allowing operators to monitor changes in real time, and during data analysis and post processing;

- Specific operating procedures and protocols for ISO 22476-1 2022, including continuity and consistency in data collection;

- Staffing projects with a trained field Engineer, Geologist, or Technologist;

- Comprehensive data review process performed by highly experienced experts on our team;

- Field operations supported by our network of site investigation professionals around the world.

ConeTec offers options for cones calibrated to ISO 22476-1:2022 Cone Class 0, 1 or 2 for any given project. Training, QA/QC practices, and upgrades to data acquisition software allow operators to tailor field practices and procedures to target Test Categories A through D, based on project requirements. Utilising the new ISO 2022 standard, practitioners are provided with comprehensive transparency of test results and an increased understanding of the level of confidence in the data collected.

8.0 Conclusion

The new calibration and field procedures specified by ISO 22476-1:2022 are a challenge for CPT manufactures and operators, but ultimately offer improved quality, verification, and transparency within the CPT industry. It is crucial to address the standard’s gap in assessing penetrometer performance at the low-end, which can be managed by collecting extra calibration points in the low-end range. For high-risk, large-scale and critical design projects that require the highest quality, ISO 22476-1:2022 is an excellent choice for directing CPTu operations.

For more information or to request a Class 0 cone for your project:

-

·Contact us at www.conetec.com/contact

-

ISO 22476-1:2022 is available here: https://www.iso.org/obp/ui/#iso:std:iso:22476:-1:ed-2:v1:en

-

QUICK LINKS