Advancing Geotechnical Testing: The Piezometer Vane System (VR-eVSTuTM)

Geotechnical site characterization is advancing with new tools that improve field testing accuracy and efficiency. One such innovation is ConeTec’s patent-pending Piezometer Vane System (VR-eVSTuTM), a commercial prototype for tailings and natural soils. This system uses ConeTec's digital vane shear testing equipment with a new innovated load cell and a specially designed vane blade. This new load cell includes a pressure transducer for measuring pore fluid pressures during standard rate and variable rate testing.

1.0 How is it Different?

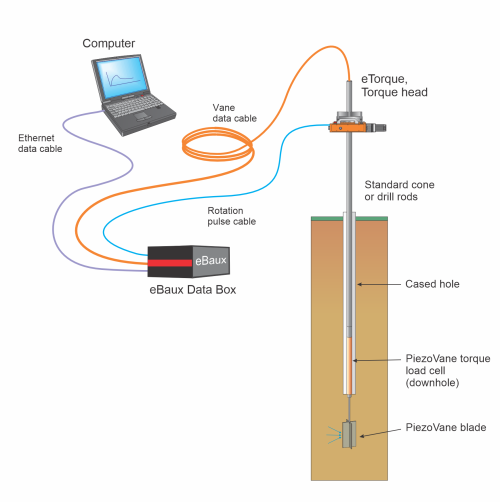

This update introduces an innovative improvement to our existing commercial tool, eVane/eTorque, which is currently offered by ConeTec to support eVST testing in the field. The system now features integrated pore pressure measurement capabilities in addition to temperature and inclination.

2.0 why it stands out?

The patent-pending design can comply with ASTM and ISO dimensions, ensuring compatibility with existing standards and comparability with typical vane tests. Built for versatility, this prototype tool offers rotation speeds ranging from 0.1°/s (ASTM VST) to 30°/s Fast Vane Shear Testing (FVST), with a maximum torque of 100 Nm, making it suitable for a wide range of soil conditions.

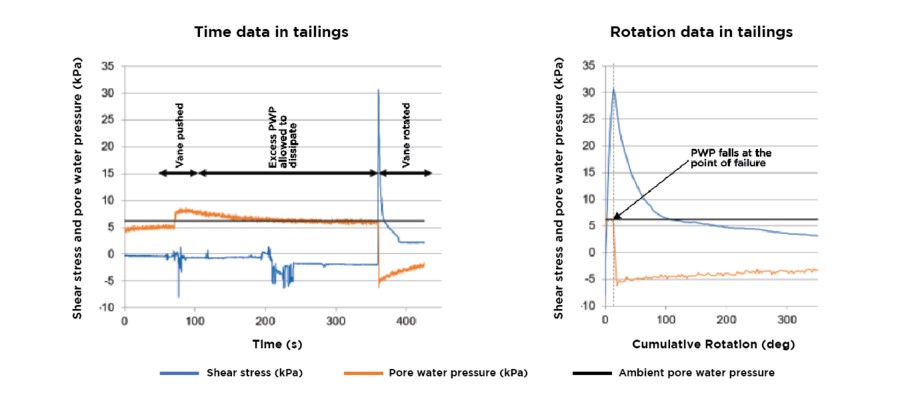

Enhancing data collection, the load cell records pore water pressure (PWP) during vane insertion, rotation and retrieval, recording PWP's generated by penetration and shear. Its downhole instrumentation provides results at low strengths and pore pressures.. The tool also includes a temperature sensor and inclinometer package.

Vane sizes available for testing shear strengths starting from less than 1 kPa.

Plots: Example time and rotation data in tailings collected with the VR-eVSTuTM system

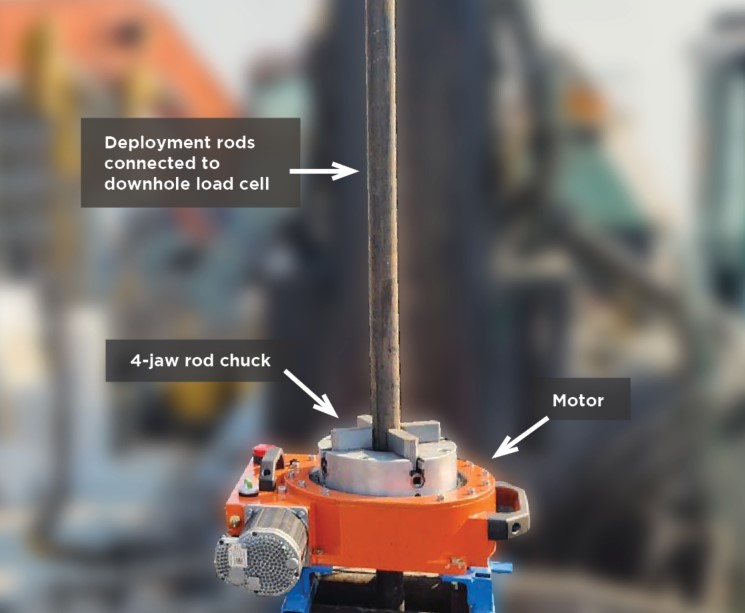

3.0 HOW THE SYSTEM WORKS

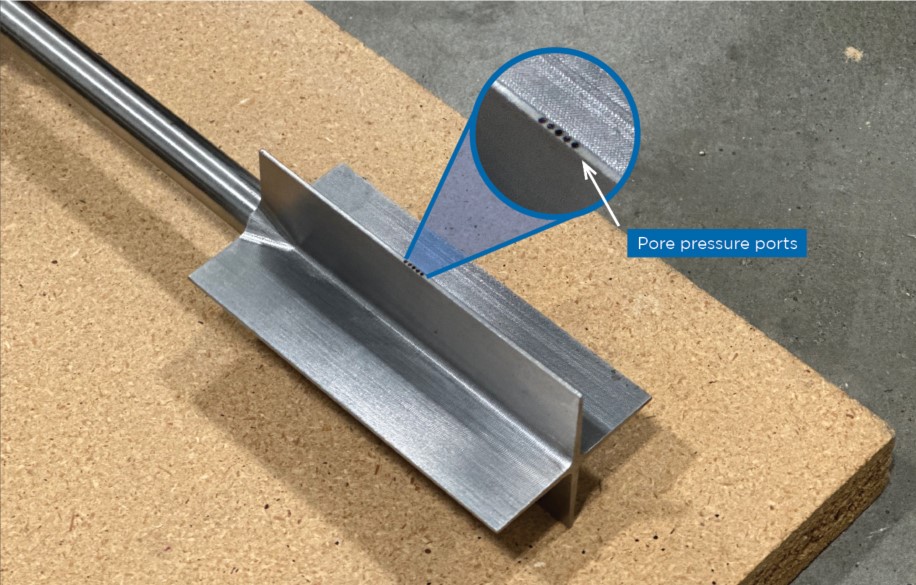

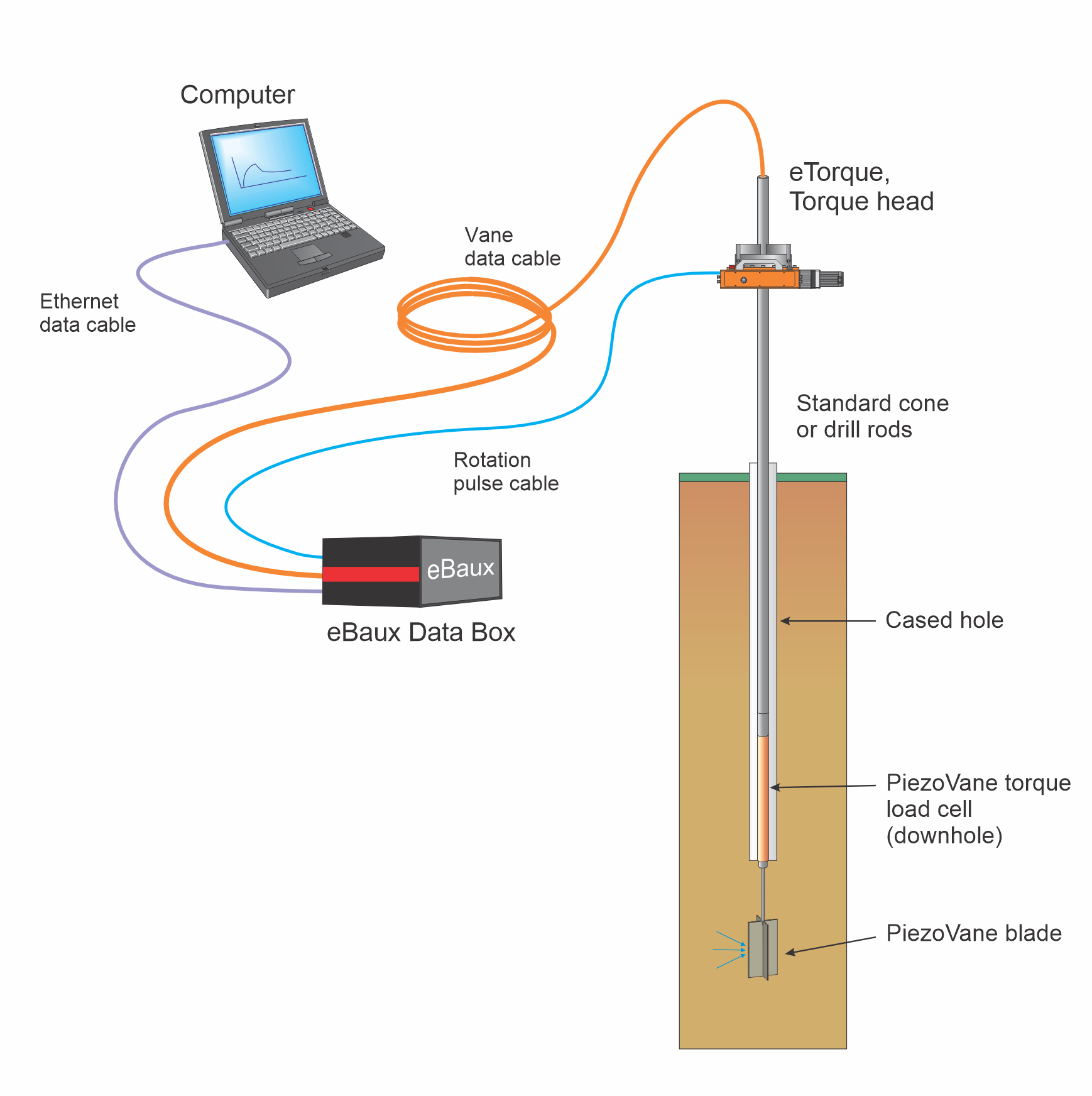

The pore water pressure measurement system is comprised of ports drilled through the vane blade, connecting with a pore water pressure transducer (piezometer) housed within the load cell.

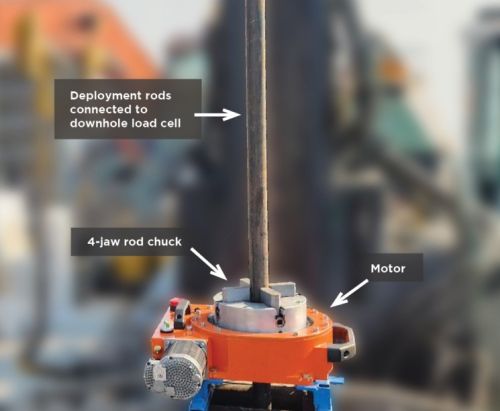

The vane system is designed with a load cell that measures the applied torque. Inclinometers are used to monitor eccentricity during testing and temperature measurements are also recorded. The system is designed to use vane blades of various sizes and configurations that connect to the load cell with an extension rod. The digital torque and pore water signals are transmitted via a cable to the data acquisition system.

The electric motor (eTorque) is designed to clamp onto and rotate the rods, load cell and vane blade. The motor captures the angle of rotation with an internal shaft encoder. ConeTec’s calibration criteria for the load cells are in accordance with industry best practices.

4.0 CAPABILITIES

ConeTec’s digital piezometer vane shear device advances vane shear testing by measuring both shear stress and pore pressure. Its capabilities include:

- Standardized rate vane shear testing with pore pressure measurements.

- Variable rate (fast) vane shear testing with pore pressure measurements.

- Provides potential insights into drainage conditions, including undrained, partially drained, and drained states during shearing.

- Designed for a wide range of materials, including natural soils and mine tailings.

- Measures peak, post-peak, and remoulded undrained shear stress and PWP response throughout shearing.

- Viscosity measurements can be taken with the same equipment in slurries and soft sediments.

Figure: Illustration of the VR-eVSTuTM system setup

5.0 Bringing New Understanding to Geotechnical Challenges

Conventional vane shear testing has faced limitations in characterizing coarser materials, where drainage or partial drainage can provide unconservative strength measurements. The VR-eVSTuTM addresses these challenges by offering a more comprehensive understanding of soil behavior, particularly in complex tailings environments. Ongoing research with this system aims to refine interpretations of geotechnical parameters related to consolidation, brittleness, and shear strength variability.

6.0 Conclusion

The Piezometer Vane System (VR-eVSTuTM) represents a transformational step in geotechnical site investigation. By integrating shear stress measurement with real-time pore pressure monitoring, this system provides insightful data for evaluating natural soils and mine tailings. As ConeTec continues to lead innovation in geotechnical testing, the VR-eVSTuTM stands as a testament to the company’s commitment to better information for better decisions.

For more information contact us at www.conetec.com/contact

QUICK LINKS